Our service encompasses the precise assembly and installation of complex steel structures for various industrial and commercial applications. It involves meticulous planning, fabrication, and on-site erection, ensuring structural integrity and adherence to stringent specifications. This service is crucial for projects requiring robust, durable frameworks, from large-scale industrial facilities to intricate architectural designs, where precision is paramount for long-term performance and safety.

This service addresses critical business needs by providing reliable structural foundations that support operational continuity and expansion. It resolves challenges related to structural stability, load-bearing capacity, and compliance with regulatory standards. Clients achieve enhanced operational safety, reduced maintenance costs, and accelerated project timelines, leading to more efficient asset deployment and sustained productivity.

Our expertise in steel structure assembly finds extensive application across diverse sectors. This includes the construction of industrial plants, warehouses, distribution centers, and manufacturing facilities. We also specialize in infrastructure projects like bridges and specialized architectural frameworks, as well as energy sector installations. The service is highly effective where structural strength, durability, and rapid deployment are essential for project success.

Uncompromising Precision: We utilize advanced laser alignment and digital surveying tools to ensure every component is positioned with sub-millimeter accuracy, minimizing errors and rework on-site.

Integrated Project Management: Our comprehensive approach covers design review, fabrication coordination, logistics, and installation, providing a seamless and efficient project flow from start to finish.

Robust Safety Protocols: Stonecraftjit prioritizes the highest safety standards through continuous training, rigorous risk assessments, and the implementation of best practices, safeguarding personnel and assets.

Tailored Structural Solutions: We adapt our methodologies to specific project requirements, offering customized solutions that optimize material usage, structural performance, and overall project efficiency.

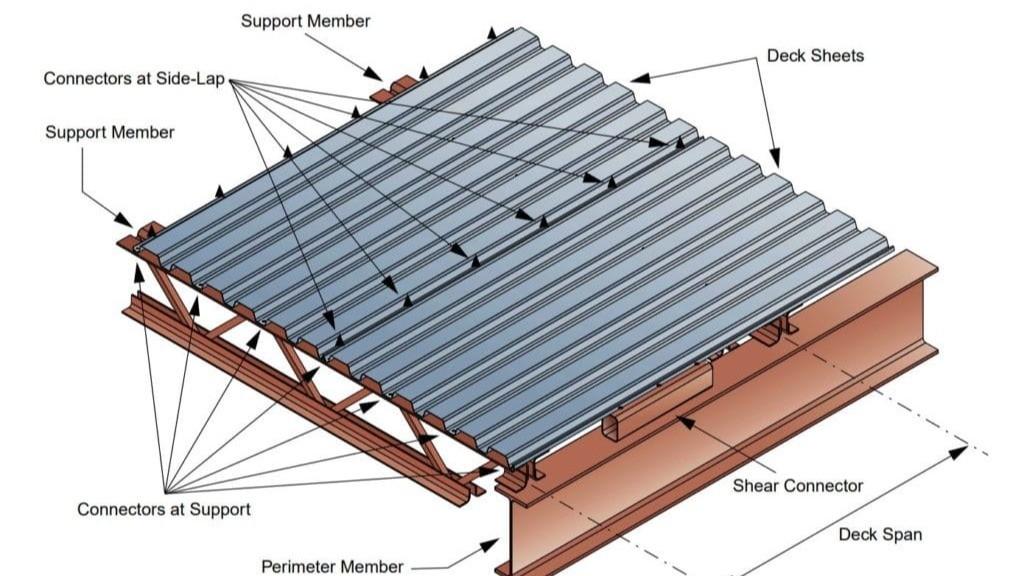

The implementation process begins with a thorough site assessment and detailed engineering review. This is followed by precise fabrication of steel components off-site. On-site, our experienced teams manage logistics, component delivery, and the systematic assembly sequence. We employ specialized lifting equipment, advanced fastening techniques, and continuous quality checks at each stage, ensuring a smooth and controlled erection process from foundation to final structural completion.

Our operations are underpinned by cutting-edge technologies such as Building Information Modeling (BIM) for clash detection and precise component visualization, alongside advanced robotic welding for enhanced fabrication quality. We adhere strictly to international structural engineering standards, including Eurocodes and AISC specifications, and implement Lean construction methodologies to optimize workflows and minimize waste throughout the project lifecycle.

Upon completion, clients experience significantly enhanced operational efficiency due to robust and stable structures designed for longevity. The solution leads to optimized space utilization and improved workflow within facilities. Furthermore, businesses benefit from increased structural stability, minimizing future maintenance needs and ensuring consistent, reliable performance for decades. This translates directly into sustained operational advantage.

Quality assurance is integral to every phase, from material sourcing and fabrication to final installation. We conduct multi-level inspections, including non-destructive testing and dimensional checks, to verify compliance. Safety is paramount, enforced through daily briefings, comprehensive hazard analyses, and strict adherence to occupational health and safety regulations. Continuous project monitoring and transparent reporting provide complete control and accountability.

Our service is designed for seamless integration with existing operational frameworks. We collaborate closely with client teams to understand their current processes, scheduling, and logistical requirements. This proactive approach ensures minimal disruption during assembly, allowing for smooth transitions and continued productivity. Our project managers align installation schedules with your broader operational plans, facilitating a cohesive project environment.

The precision steel structure assembly and installation service from Stonecraftjit is a cornerstone for building resilient, high-performing assets. It provides the foundational strength necessary for business growth and operational excellence. By delivering structures combining durability with optimal functionality, we empower organizations to achieve strategic objectives, ensuring long-term stability and sustained success.

Choose color scheme